PRE-ENGINEERED BUILDINGS

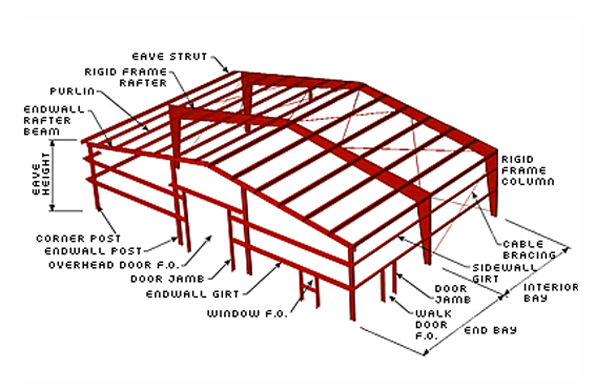

There is almost no limitation in facing materials that can be used, from standard, color-coated steel panels to masonry or glass. The real measure of Pre-Engineered Buildings quality lies in the system itself. The design, assembly and fit of beams, girts and purlins are critical to the integrity of the structure.

The Building shall include the structural framing, roofing, siding, bracing, doors, windows, hardware, fasteners, sealants and any other component parts for the metal building as specified or shown on the drawings.

DESIGN CODES

All Structural steel sections and welded plate members shall be designed in accordance with American Institute of steel construction (AISC) and Metal Building Manufacturer Association (MBMA). All light- gage, cold-formed, structural members and coverings shall be designed in accordance with the latest edition of the American Iron & Steel Institute "Specification for the design of Cold-Formed Steel Structural Members". Design calculations will be provided upon request. With the pre-engineered buildings approach, you can expect about 30% lower in cost than conventional steel.

DESIGN LOADS

The loads considered shall be clearly expressed in our proposal offers. The building shall be designed to safely resist these loads. Loads are applied in accordance with the International Building code (IBC) latest edition). Load combinations shall also be in accordance to the IBC and MBMA codes.

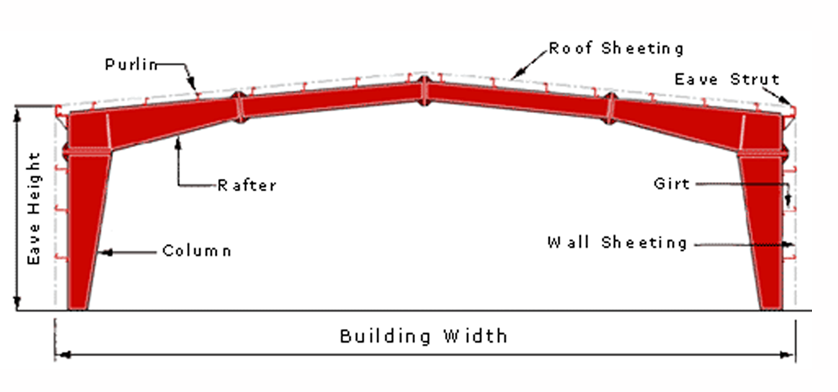

BUILDING COMPONENTS

All framing members are shop fabricated for bolted field assembly. All members are cleaned by mechanical brushing, sand or shot blasting to remove dirt, grease, loose mill scale prior to paint application where necessary. The paint is applied on black steel as per customer specific request or one coat of oxide primer.

PRIMARY STRUCTURE

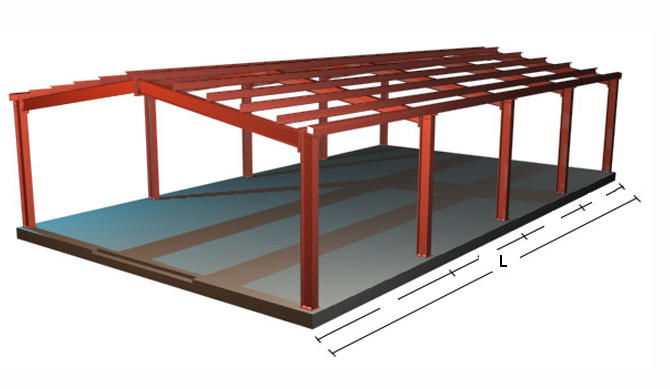

To provide you with your optimum, most cost effective DSI Pre-Engineered Buildings, we will need to discuss frame type required, and building specifications like width, length and height.

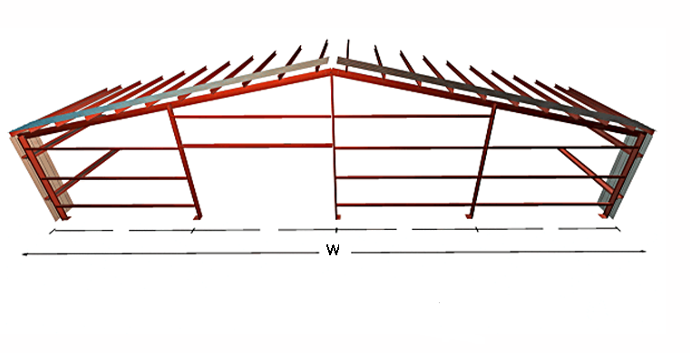

BUILDING WIDTH

The building width can be defined as out-to-out from the back sidewall to the front sidewall outermost steel lines. Building width can also be defined as center-to-center, center of the anchor bolts of the rigid frame columns.

BUILDING LENGTH

The building length defines the outermost steel lines from the left end wall to the right end wall. Bay spacing (distance between frame columns) is then taken as most optimized or should be given for pre-defined existing foundation layout.

BUILDING HEIGHT

Building height will by default be understood as the eave height, the distance between the finish floor level and the point where the sidewalls meet the roof. For further design limitations, customer can also define the minimum clear height required, the distance finish floor level to the lowest point under the rafter beams.